How Automotive Testing Technology Conquers Development Challenges

Testing Technology: The Driving Force of Automotive Development

Vehicle development requirements are rapidly changing. Innovations in the automotive industry - including autonomous vehicle development and the introduction of sustainability measures - are pushing the boundaries of current automotive testing capabilities. With the scope of requirements expanding, automotive engineers need more efficient ways to drive testing and development efforts forward. This comes down to the testing technology available.

Automotive testing technology is instrumental in assessing the safety, performance, quality and processability of a design or prototype. The proper test equipment provides repeatable, reliable results and supports engineers in the testing process. Ultimately, the collected data helps engineers determine which designs will go to production and which must be scrapped or tweaked for better performance. Development testing is crucial to provide the safest product possible, meet regulation and design requirements, and avoid recalls of components. By placing an emphasis on reliability in product development testing, we can ensure that we deliver a quality final product, and avoid costly mistakes.

Component Development Testing

As the world shifts towards sustainable manufacturing, automotive engineers are required to consider and test a wider variety of metrics at the outset of product design and development. Now automotive engineers must consider the recyclability, regulatory compliance, carbon footprint, and social responsibility of their designs. In addition, the spread of autonomous vehicle functions requires automotive components to be tested in new ways.

The sheer number of test scenarios that must be evaluated is ever-increasing for automotive manufacturers. Industry leaders foresee bottle-necks in development being streamlined by more robust testing technology. The tire industry may have the most to gain from more efficient testing tech.

Tire Testing

Tire design is much more complex than most consumers think. Over 200 materials can be involved in tire production and a variety of processing methods are used to produce the tread, belts, sidewall, body piles, beads and inner liner that make up a typical passenger tire. Each of these factors have an influence on the final performance and quality of the tire, highlighting the need for development testing. Tire testing and development can be categorized into static and dynamic testing conditions.

Static Tire Tests

Static tire tests occur on a motionless tire. The strength and durability of the tire compound is heavily evaluated at this stage. Automotive engineers gather an array of static variables, including:

- main dimensions & weight,

- the unbalance of tires,

- stiffness,

- fracture points,

- bruise resistance, and

- tire footprint.

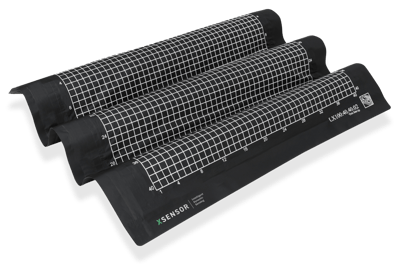

Test engineers use these preliminary metrics to rate the durability, quality and safety of a particular tire design. The footprint test, for example, measures the way the tire interacts with the road (or contact patch) and is one of the most important static tests. Automotive engineers position the vehicle on a mat of pressure sensors, and the resulting data shows static forces and moments on the tire. This is critical to helping design engineers understand how wear occurs on the tire.

Dynamic Tire Tests

Dynamic tire testing focuses on evaluating the tire in “on-the-track” conditions. Tires are tested mostly outdoors in real-world conditions of varying temperature, incline, and road-surface. Dynamic tire testing depends on high-speed test equipment, sensors and data acquisition software to capture the behavior of the tire in motion.

The multiple phases of dynamic tire testing begin with nailing down the tire profile and tread pattern. The dynamic footprint test, which shows the contact patch of a moving tire, is performed in this phase. A few indoor tests, such as endurance testing, make use of a dynamometer to determine the loads and speeds a tire can endure before failure. Engineers must also test the force required to maintain forward motion at a constant speed, or rolling resistance; The less force required, the greater the fuel mileage.

Dynamic outdoor tests observe the tire in a wide variety of practical and extreme use cases, allowing engineers to capture crucial data metrics for

- Wet and dry traction,

- Snow traction,

- Stopping distance,

- Noise,

- Handling and consumer-feel.

Challenges in tire testing

Tire development and testing can take up to three years for a completely new tire design. Improvements or alterations to existing tire designs can take anywhere from 6 to 9 months. Sustainability is a huge concern for the tire industry and will likely add to this timeline.

In the future, advanced simulations will allow automotive engineers to test multiple scenarios at once, to shorten the development timeline and allow manufacturers to keep up with the growing number of testing requirements. Simulated models, however, must be heavily verified by physical test data before they can be relied upon to provide accurate results.

Seating Tests

The seats in our vehicles go through rigorous testing to ensure exceptional safety and comfortability after driving thousands of miles. The job of the development testing process is to simulate years of usage and examine every possible strain that could be put on a vehicle seat in the real-world.

In seat testing, the fabric and foam are subjected to up to 100kg loads and more than 20,000 friction cycles using robotic test equipment and real people. One seating test uses pressure mats to first map out the exact pass pattern a person’s body makes when entering and exiting the car seat. In the next phase, a robot shaped like a metallic buttox repeats this pass pattern for thousands of cycles, simulating ten years of use. Such tests can be completed in 3 to 6 weeks.

The most rigorous seat tests which help automotive engineers to evaluate durability and safety are:

- A fatigue test reproduces driving on uneven surfaces for 300,000 km.

- An environmental test exposes seats to extreme hot and cold temperatures, and a thermographic camera verifies that heat is spread evenly.

- Seat & safety restraint reliability testing utilizes a mechanical sled to generate pulses for a wide variety of vehicle impact scenarios.

Challenges in seat testing

As the expectation for eco-friendliness and recyclable materials grows, more companies will have to follow suit to develop and test sustainable seating materials and fabrics. The challenge is to increase recyclability without sacrificing on quality or consumer-feel. In the future, AV will change the way people sit in cars and thus change the testing process and criteria. This will also pose huge changes for automotive crash testing.

Crash Tests

The safety of our vehicles has increased dramatically in the past 20 years. This is most apparent in crash testing. Agencies like the IIHS and NHTSA conduct tests on popular passenger vehicles. By this time though, hundreds of crash tests have already been completed in the vehicle development phase.

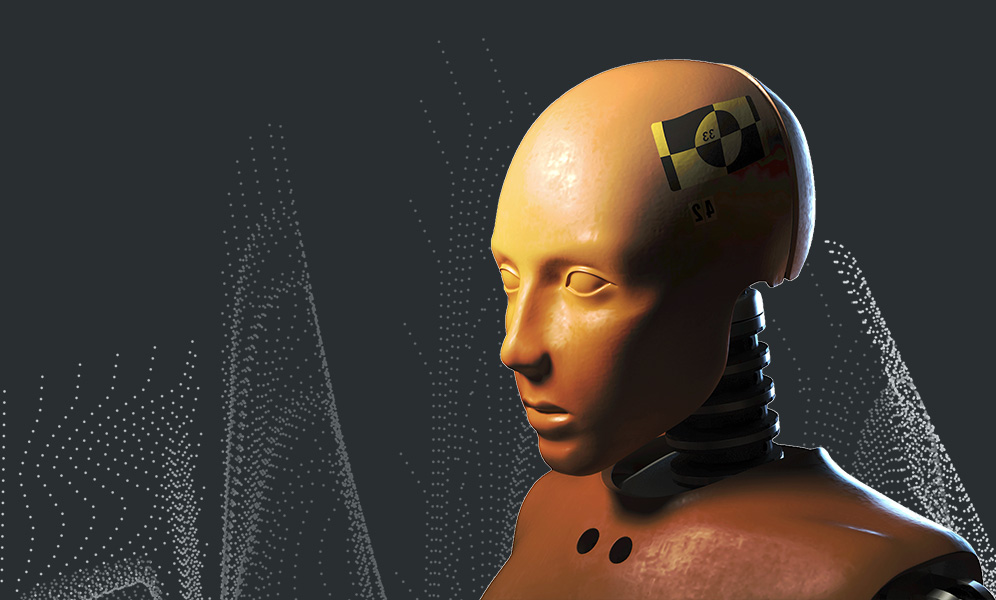

In most crash tests, the car’s fuel is replaced with a less volatile liquid. Engineers prep the car with black and yellow inch tape and targets, used to measure deformation during the crash. Cameras and dummies equipped with accelerometers, motion sensors, and pressure sensors, are carefully placed in the car. The test takes place in a brightly lit lab, where high-speed cameras capture details of the collison. Automotive engineers conduct these crash tests, tweaking the parameters many times to understand how the car will behave in different crash scenarios:

Engineers prep the car with black and yellow inch tape and targets, used to measure deformation during the crash. Cameras and dummies equipped with accelerometers, motion sensors, and pressure sensors, are carefully placed in the car. The test takes place in a brightly lit lab, where high-speed cameras capture details of the collison. Automotive engineers conduct these crash tests, tweaking the parameters many times to understand how the car will behave in different crash scenarios:

- Airbag deployment.

- Frontal, side impact, and rollover crash testing.

- Sled testing to evaluate collisions with belted and unbelted passengers.

- Head impact and injury testing.

- Crash simulation evaluates unsecured objects or projectiles in the car.

- Evaluation of the bumper.

- Seat belt strength and pull testing.

The passenger-carrying compartment of the car is called the survival space. Design engineers work to minimize the deformation that can occur for the highest level of vehicle safety.

Challenges in crash testing

Manufacturers already face a barrage of testing requirements to satisfy the differing regulations of countries around the globe. Auto accident deaths in the US approach 40,000 per year, and autonomous driving and advanced driver-assistance systems seek to quell this problem. As these innovations become more widespread, new testing methods and technology will be adopted for automotive testing. Similar to the tire industry, leaders in crash testing speculate that digital modeling will replace the large-scale use of test dummies, simplifying the development phase for automotive engineers.

Technology to optimize development testing

Integrating intelligent dynamic sensing into your team’s design and development methods can significantly improve both consumer outcomes and automotive testing operations, reducing staff workloads and increasing efficiency.

XSENSOR offers solutions for high speed sensing and data logging, giving automotive engineers reliable, accurate, high resolution data to inform design decisions - and ideally, accelerate lead times for new product development - for the highest levels of safety and performance.

XSENSOR’s Intelligent Dynamic Sensing technology is specifically designed to help engineers maximize precision, reliability, and accuracy in dynamic sensing and provide actionable product performance insights using advanced analysis and visualizations.

- For static tire testing: Our X3 Tire Testing system provides automotive engineers detailed contact patch data for passenger, commercial, and industrial tires, critical to understanding tire performance. Integrate with our Pro software to assess pressure profiles and make calculations to compare tire mechanics.

- For dynamic tire testing: Our High-Speed Tire Testing system uses new HX sensor technology and ultra-fast signal processing electronics to capture dynamic footprint data in real-world conditions of speed, temperature, incline, tire angle, and road surface.

- For seat testing: Our X3 Pro Seating system uses state-of-the art LX sensors to evaluate seating performance with outstanding repeatability for ingress/egress, durability and comfort testing. Our unique system provides detailed interface pressure measurements on the seat and back surfaces to assess ergonomics and injury prevention.

- For crash testing: Our HS Impact solution provides detailed analysis of surface pressures during and after collisions. Our data logger attaches to crash sleds and enables repeated testing, and integrated software allows engineers to analyze and view live or post-process data.

At XSENSOR, we support automotive engineers in conducting the most accurate, precise, and reliable design and development tests through intelligent dynamic sensing technology. Contact us today, and we’ll raise your standard of testing together.