Currently, there are two methods that are commercially available to capture a full tire contact patch while rotating at speed:

-

In-Track Camera System: Involves building infrastructure under a test track with a glass plate is embedded into the track surface. Below the track a high-speed camera is pointed up at the glass plate to capture the tire image as the vehicle rolls over the plate. This method provides high-quality photos which can be extrapolated to an image with color representing loads.

-

3-Axis Load Cell Array: Can measure x, y, and z-axis forces and provides information of load as a tire passes over the line of sensors. The software then generates a profile of the tire patch.

Until now, there has not been an effective and portable option to provide accurate high-resolution tire footprint pressure measurements for dynamic testing.

High-Speed Pressure Imaging Technical Considerations

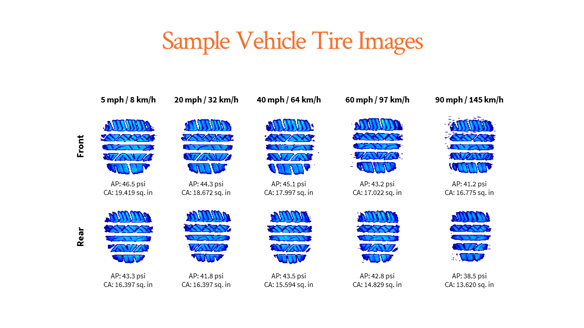

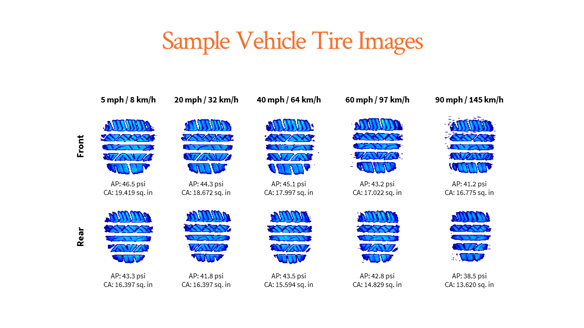

Advances in sensor design and technology have enabled measurements of dynamic pressures on tire contact patches with ultra-fast sensors, recording, and response speeds. High frame-rate and sensor response are important because it ensures the profiles of the rolling tire are captured. If the frame-rate is too low, critical peak pressure and load data will be lost.

A high spatial resolution allows the user to visualize the fine details in a tire such as the sipes, grooves, tie bars, and notches. Using a sensor with too low a resolution will blur these features and prevent the user from seeing the dynamic interaction that these features have with rolling speed.

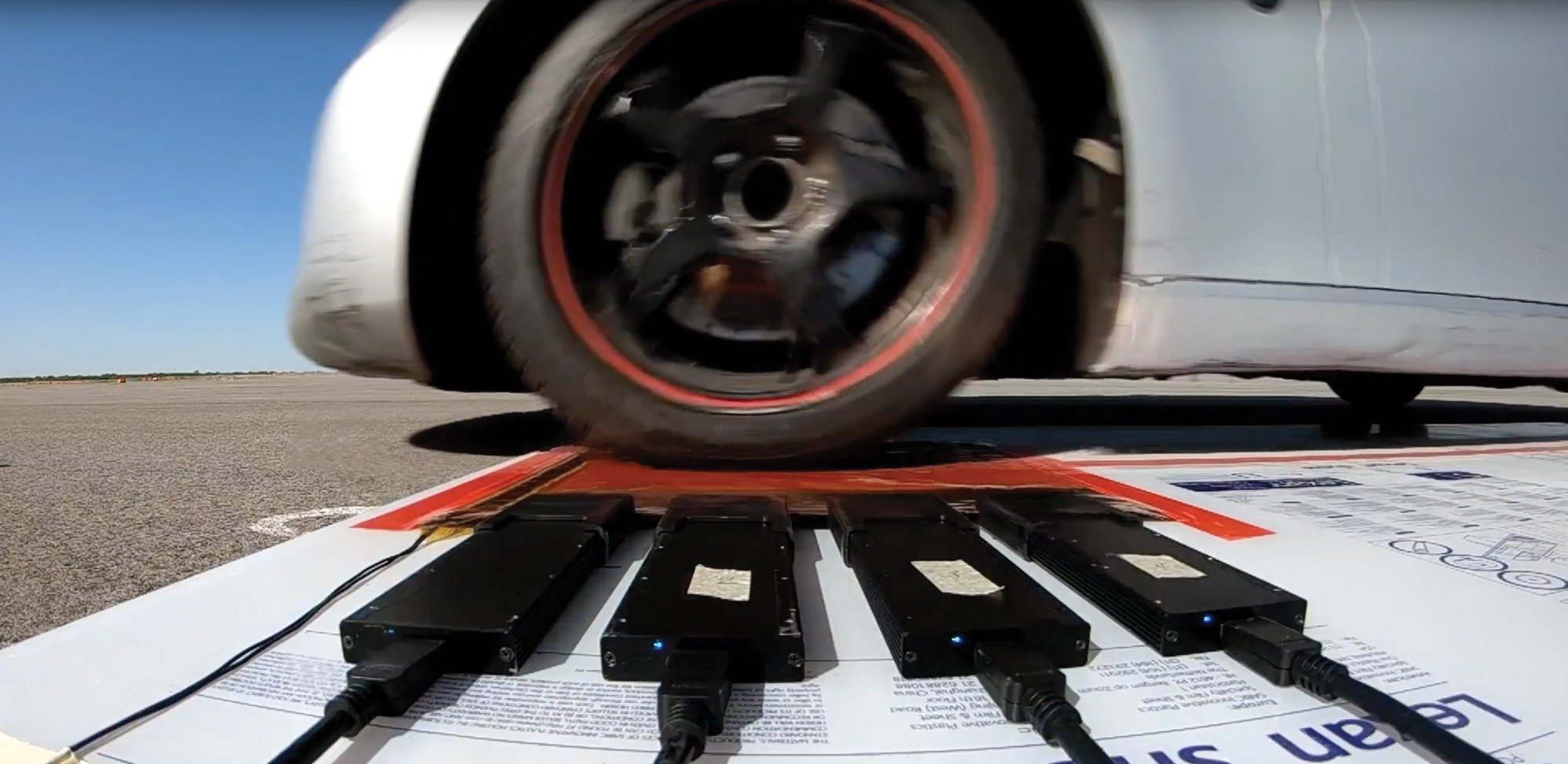

Another aspect to consider is portability. Systems now offer fast set-up and the ability to move from one test track to another, or be able to move to different parts of the test track. Portability, and bringing your system from your lab to the track, should be at top of mind.

How XSENSOR’s High-Speed Tire System is different.

The XSENSOR High-Speed Tire system allows users to capture the tire contact and pressure data at speeds up to 150 km/h. The system can be assembled and configured to record data in as little as 10 minutes and can be easily transported with you from your lab to the test track. With this flexibility, several test scenarios can be captured in a single session.

The system captures clear, full, and high-resolution images at any speed. The data is available within seconds of recording and little to no post-processing is required. This enables engineers to review data immediately while on the track, make adjustments, and get immediate feedback on the changes.

Watch our free on-demand webinar today to learn more about advances in sensor technology and how the High-Speed Tire System can help optimize your tire designs.

Download the High-Speed Tire System brochure to learn more.