The Importance of Static Tire Testing

What static tire testing entails and why it is a crucial part of the tire development process.

Testing tires under real-world conditions while in motion - also known as dynamic tire testing - is an essential part of a tire's performance testing process. In addition to testing how a tire performs while it is in use, it is equally important to test the overall strength and durability of the tire compound when developing tire technology. For this objective, static tire testing is the go-to solution.

This article will cover what static tire testing is, why it is necessary, and how XSENSOR's X3 Tire Testing System is revolutionizing the static tire testing process.

What is Static Tire Testing?

Static tire testing in the automotive industry entails performing tests on a static or motionless tire. For a tire manufacturer, static tire testing is essential to ensure that the strength of the tire compound is up to standards and gather data on other key variables for passenger cars.

Variables that are gathered in static tire tests include:

- Dimensions and weight of the tire

- The tire's balance

- Tire footprint

- Stiffness

- Fracture points

- Bruise resistance

These data points provide engineers with a more comprehensive picture of a tire's durability, quality, and safety. Testing for fracture points and bruise resistance, for example, helps ensure that the tire compound is durable enough to avoid damage before the end of its life cycle. The tire footprint test provides data on a tire's contact patch or how it interacts with the road.

Since a wide range of variables is measured during the static tire testing process, a wide range of test equipment is typically used. Perhaps the most critical piece of this test equipment is a mat of pressure sensors that enables engineers to conduct load testing and collect data on the static forces and moments present when the tire is in contact with the ground.

Static Tire Testing Vs Dynamic Tire Testing

Static tire testing and dynamic tire testing are both crucial steps in developing high-quality tires for vehicles during vehicle development. However, the variables that these two testing processes measure and how they are conducted are quite different.

Dynamic tire testing entails placing the tire on-road vehicles and testing its performance on the track to analyze key performance metrics such as handling and feel, wet and dry traction, stopping distance, and noise. While dynamic tire testing is designed to gauge a tire's real-world performance, static tire testing is more focused on evaluating the overall strength and durability of the tire compound. Static tire testing provides key data on several metrics beyond strength and durability, such as assessing the tire footprint and the tire's balance.

Along with seating tests and crash tests, static tire testing and dynamic tire testing are two of the most important testing processes conducted by the automotive and tire industry. Combined, static and dynamic tire testing can provide engineers with a complete picture of the performance, safety, and overall quality of a tire design.

Challenges of Static Tire Testing

Challenges of Static Tire Testing

Since static tire testing is conducted on a motionless tire, it is an inherently more straightforward testing process than dynamic tire testing within the control system. With dynamic tire testing, engineers are tasked with collecting data on a tire while moving at high speeds, which can be a real challenge. To make the challenges associated with dynamic tire testing much easier to overcome, XSENSOR has developed a High-Speed Tire Testing System that utilizes HX sensor technology and ultra-fast signal processing electronics. Engineers can easily collect a wide range of data even while the tire moves at high speeds and other extreme testing conditions.

While static tire testing may not present as many obstacles as dynamic tire testing, it still comes with its own unique set of challenges. One such challenge is that static tire testing requires engineers to collect data on a broad range of metrics, requiring engineers to employ an equally wide range of testing equipment, slowing down the static tire testing process. Another challenge of static tire testing is that engineers need to be able to ensure that the data they collect is accurate and repeatable. Without the right tools, the data collected by static tire testing isn't always completely reliable.

At XSENSOR have developed the perfect solution for helping engineers overcome these static tire testing challenges: the X3 Tire Testing System.

How the X3 Tire Testing System Improves the Static Tire Testing Process

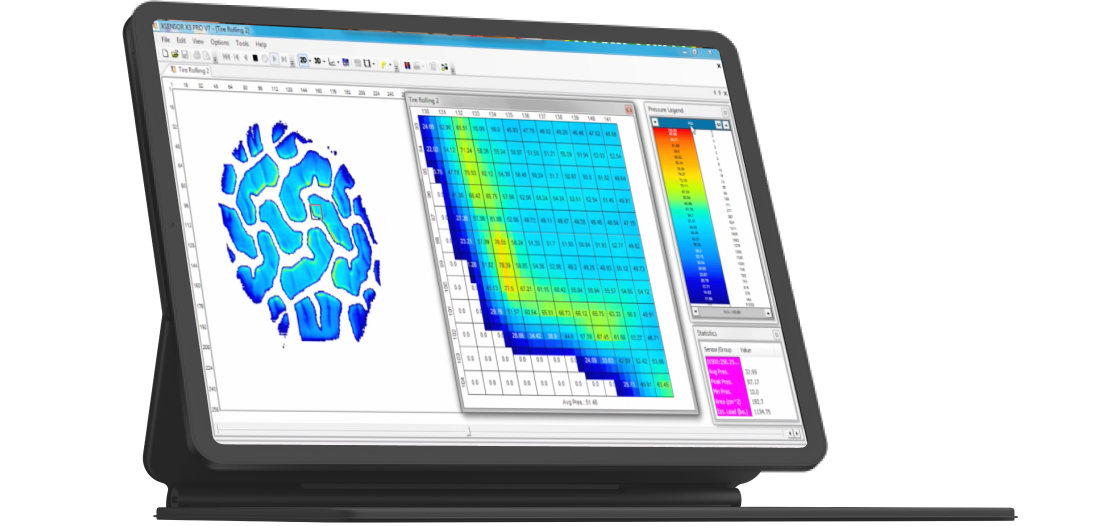

Our X3 Tire Testing System is a mat full of high-resolution sensors that provide engineers with detailed tire footprint images that can be used to analyze all of the key metrics in the static tire testing process. The data that this sensor mat collects is then transferred to our built-in Pro software, which allows engineers to assess pressure profiles and make specific measurements and calculations to evaluate the mechanics of a tire design.

The biggest advantage of our X3 Tire Testing System is that its high-resolution sensors provide accurate, reliable, and repeatable data, thus taking all of the guesswork and room for error out of the static tire testing process. Another key benefit of this system is that it can streamline the testing process by allowing engineers to collect a broad range of data in a single test to quickly analyze that data and perform necessary calculations via the system's Pro software.

To learn more about our X3 Tire Testing system for static tire testing, our High-Speed Tire Testing System for dynamic tire testing, or any other industry-leading testing equipment, products, and services that we have available, be sure to contact us today.