Vehicle Impact Measurement Devices: Crash Test Sensors

How Crash Test Sensors Improve Testing Outcomes and Design Speed

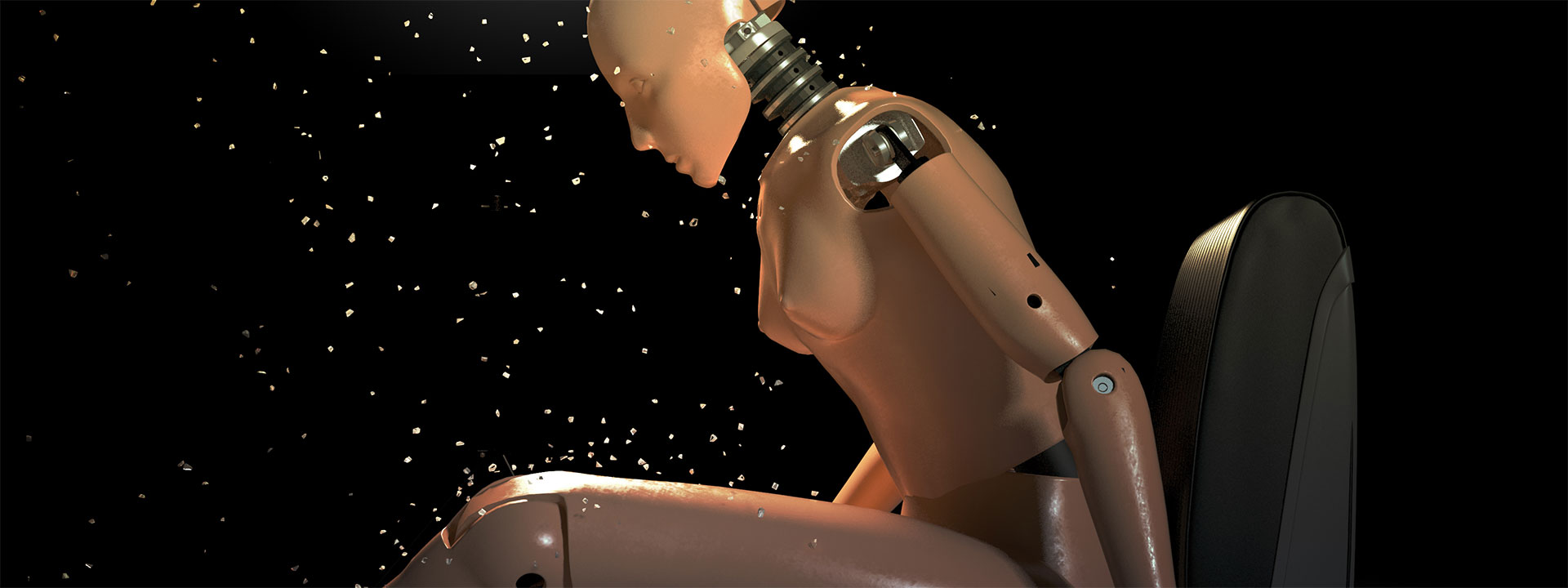

Car accidents happen quickly, and the average person has no ability to track how they unfold. Before the invention of crash test dummies and systems that could gather data in real-time, the field of safety performance was largely guesswork, informed by data gathered at the crash site – including fatalities.

Today, we have much better sources of data. Modern technology allows us to comprehend varied concepts such as force, torque, pressure and speed – all vital facets of understanding how vehicles and their occupants are affected by a crash.

Crash Test Sensors: A Spotty Performance

Someone in the US has a car accident every minute. That adds up to 5.25 million accidents annually, with 38,000 fatalities. This trend means it is vitally important for automotive engineers to prioritise safety among their vehicles’ many features.

In many situations, however, crash test sensors get damaged, fail to collect enough information or collect data at the wrong points in the test. This requires teams to repeat the same test repeatedly, costing the company time, money and effort.

Moreover, not all crash test sensors can keep up with testing demands, from real-time and post-processing data to exact pressure points on the Thor ATD testing dummies. By incorporating high-quality crash test sensors capable of delivering a high level of data quickly and accurately, your team saves time, so you can spend it on adding even more safety features to your vehicles.

Why Use High-Quality Crash Test Sensors in Crash Tests?

Crash tests take place in a very short period of time. During that time, however, a rich and varied data set occurs – if you have the technology to measure it, that is. Not many sensor systems can, meaning you need to repeat the same tests over and over again.

This is an expensive process in terms of both labour and materials. Using high-quality crash test sensors to record a wider range of readings in a shorter amount of time cuts the need for repetition significantly. Add in a sensor system that conforms neatly to your Thor ATD dummy, and your data skyrockets in quality.

Spend less time developing vehicles that barely meet the standards to begin production, and more time exceeding those standards and taking over the market.

XSENSOR Crash Test Technology Features

Here’s a rundown of how our unique resolution crash test sensor technologies operate to get you the best, most reliable, most comprehensive data in real-time – the first time.

- Our hardy data collection unit can be mounted to the frame, keeping it securely in place. Designed to withstand extreme forces, it will deliver results long after many other data collection units have failed.

- Our flexible, thin sensor packages allow you to record a large number of data points in the area of interest so that you can see exactly where the problems are in your design. At the same time, you'll get readings from thousands of sensors at speeds between 2,000 and 5,000 times every second.

- You use those data points to recreate every microsecond of the crash, including what forces are at play in what locations. If you need to look at particular forces at a particular range for your test, we've got a sensor package for that.

- Review your data in real-time or post-processing to get a clear understanding of problems, as well as areas that you can fine-tune to improve your outcomes.

With this information available, engineers will be able to make smart design changes quickly, instead of having to undertake test after test.

Going Past Crash Test Sensors to Solid Software

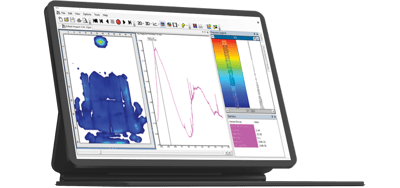

So once you have all those data points, how do you process them?

XSENSOR's high-speed, high resolution impact sensors make the process fast and easy, with powerful software that can handle the data points immediately. Instead of having to wait on an analytics program to crank through the process, you can get high-quality visualisations and an immediate picture in the form of a data graph, allowing you to react quickly to big problems. With an intuitive dashboard, your team will be able to sail through the whole testing process without a hiccup. Together, our software systems allow you to:

- Fast set-up and trigger the data logger remotely, which makes your overall process more efficient

- Synchronise the data from your sensors with your other data-gathering tools to get an eagle's eye view of what's happening during the test

- Correlate what issues resulted in what consequences for your project

- View the and compare impact in different designs, modifications and scenarios, so you can better determine how well your design will hold up in real-life circumstances

- Run test after test without recalibrating, making your entire process more efficient – and avoiding a common problem that crops up for many manufacturers of crash test sensors

These benefits allow you to collect data from a wide range of points using our available packages. With granular details available on a sensor-by-sensor basis, you can determine exactly what happened in the impact, making your redesign and modification process run more smoothly, and giving you better outcomes overall.

With a strong focus on helping the automotive industry find superior solutions in protecting vehicle occupants from serious injuries or even death, XSENSOR is proud to offer our wide range of crash test sensors to meet your company's needs.