Crash Test Dummies: Advanced Sensors Revolutionizing Vehicle Safety

The Evolution of Dummy Car Crash Test Technology

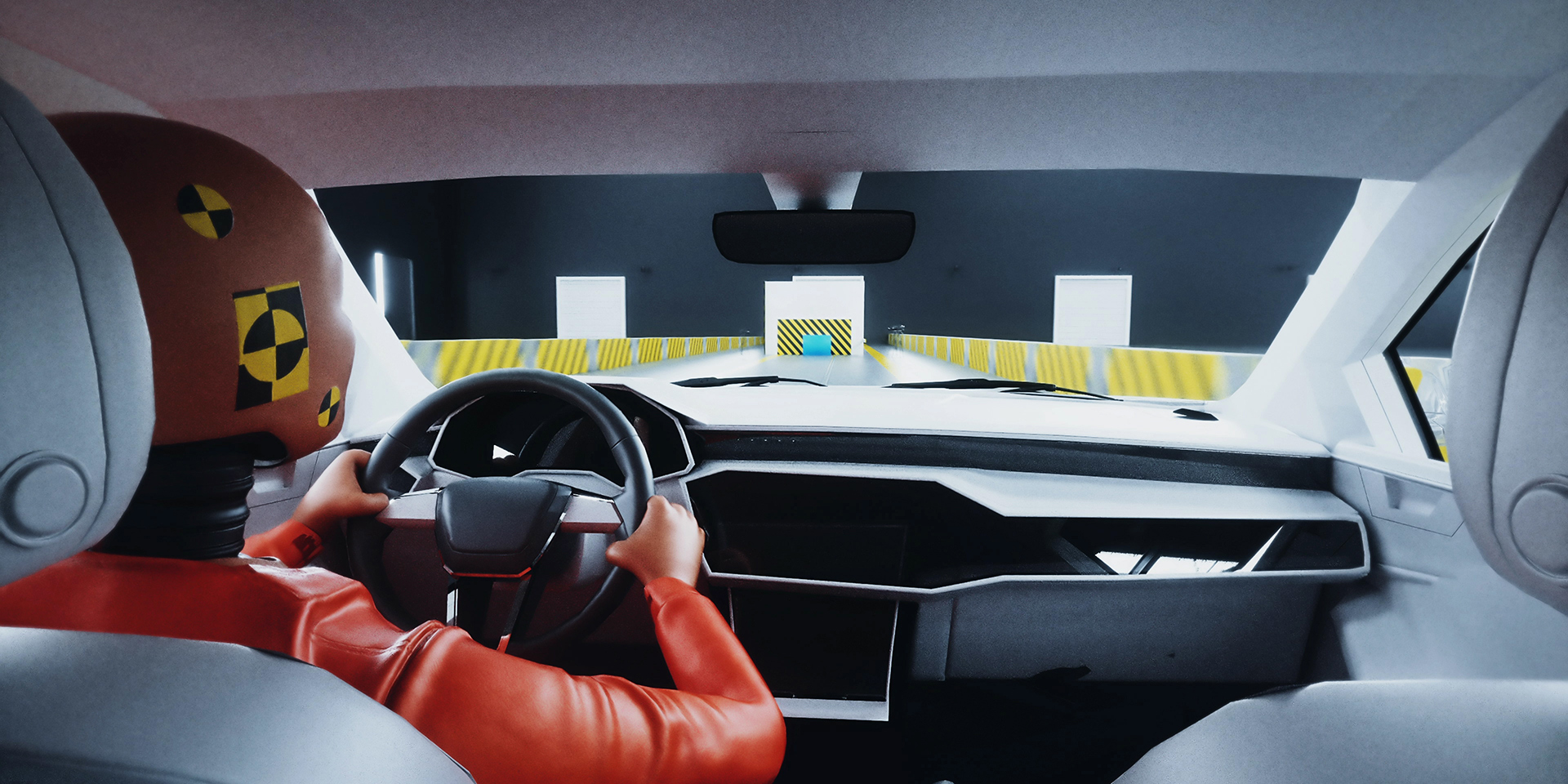

One of the most significant leaps forward in car safety technology was the invention of crash tests and dummies. Whether you're testing a frontal impact, rear impact or side impact, auto crash test dummies allow you to assess injury potential and impact forces without subjecting humans to the dangerous conditions of car crashes. With the revolution of crash test dummy sensors, these abilities have increased exponentially, transforming how we understand and improve vehicle safety.

Such technologies have already enabled us to make high-precision adjustments to engineering and manufacturing. These account for the vulnerability of various body parts, the weaknesses of car structures and restraint systems, and overall vehicle safety. However, crash test dummies of yesteryear did have some serious drawbacks that modern sensor technology has largely overcome.

From Basic Testing to Advanced Biofidelity

We've come a long way since the 1990s when the National Highway Traffic Safety Administration (NHTSA) launched its first research and development project to test crash dummy performance. At that time, automobile crashes resulted in 41,534 deaths per year, on average. Today, crash test dummy sensors have completely reinvented the use of the anthropomorphic dummy, contributing to a dramatic reduction in fatalities.

"Although the U.S. population has been growing steadily since 1975," says the Insurance Institute for Highway Safety (IIHS), "crash deaths per 100,000 people in 2019 is about half of what it was four decades ago."

In 2019, the number of people who died in motor vehicle accidents dipped under 37,000 – a 2 percent decrease from 2018. This improvement is partly due to advanced impact measurement devices and sophisticated car crash test with dummies protocols.

The Limitations of Traditional Crash Test Dummies

Dummy technology is more than 60 years old. In that time, we have improved it by leaps and bounds, but only recently have digital systems brought dummies fully into the modern age. Formerly, dummies were limited by the data acquisition system with a limited number of sensing points. They showed what happened to the human body during a crash using camera technology and rudimentary sensors, allowing measurement of basic metrics such as:

- Force of impact

- Deceleration rates

- High-pressure zones

- Where the human body was impacted

- The overall safety of the testing vehicle

However, video couldn't capture everything happening during a crash. Plus, with only basic crash test dummy sensors (or none), it was difficult to understand what was occurring moment by moment, making it challenging to address issues and create safer vehicles.

How Modern Crash Test Dummy Sensors Work

Today's advanced sensor systems create a comprehensive network of pinpoint data readings across the body and passenger interfaces. During testing, hundreds of individual sensors positioned throughout the dummy gather a wide variety of data in real-time, including:

- Impact velocity and acceleration/deceleration rates

- Passenger position by body part (head, neck, back, etc.)

- Applied force across multiple body parts

- Chest compression and joint/bone load

- Pressure patterns from restraint systems such as seatbelts and airbags

- Body interaction with seat components (bottom, back, and headrest)

- External impact effects on internal forces

- Head and face vulnerability mapping

Each reading gets transmitted to an onboard data acquisition system, where they are gathered and compiled into meaningful data that shows what's happening at every point during the crash. The most useful crash test dummy sensors gather thousands of readings per second, allowing for a picture of the simulation far superior to what video can capture.

XSENSOR’s Gold Standard Crash Test Dummy Technology

XSENSOR represents the pinnacle of crash test dummy sensor technology, offering state-of-the-art solutions backed by decades of testing industry experience. Our advanced software platform and sensor solutions work seamlessly together to deliver highly detailed, fully analyzable, and actionable data for each microsecond of the crash.

With XSENSOR sensors, engineers can break down each simulation into rich datasets and granular 3D visualizations, seeing exactly what happens during a vehicle impact test without missing critical details. Our systems provide complete integration with sensors, software, and analysis tools ready to use right out of the box, enabling rapid setup and testing.

XSENSOR's High-Speed Impact System software provides unprecedented resolution for informing design decisions and manufacturing processes, helping clients capture comprehensive pressure range and sensing area data that offers an accurate, complete picture of impact interfaces during vehicle crashes.

Spend less time recalibrating and more time gathering the data you need to build a sturdy, reliable and trusted brand. XSENSOR is here to help with comprehensive automobile safety solutions and platforms, so don’t hesitate to get in touch.