ISO/IEC 17025 – General Requirements for the Competence of Testing and Calibration Laboratories is the most important global standard for laboratories that carry out calibration and testing procedures. Manufacturers that meet the ISO/IEC 17025 standard are recognized internationally for their commitment to developing equipment that provides the highest quality of test results.

As part of the strict accreditation process, a laboratory’s quality management system is thoroughly evaluated on a regular basis to ensure continued technical competence and compliance with ISO/IEC 17025.

Organizations must prove the following:

- Their entire calibration process and equipment is well-defined;

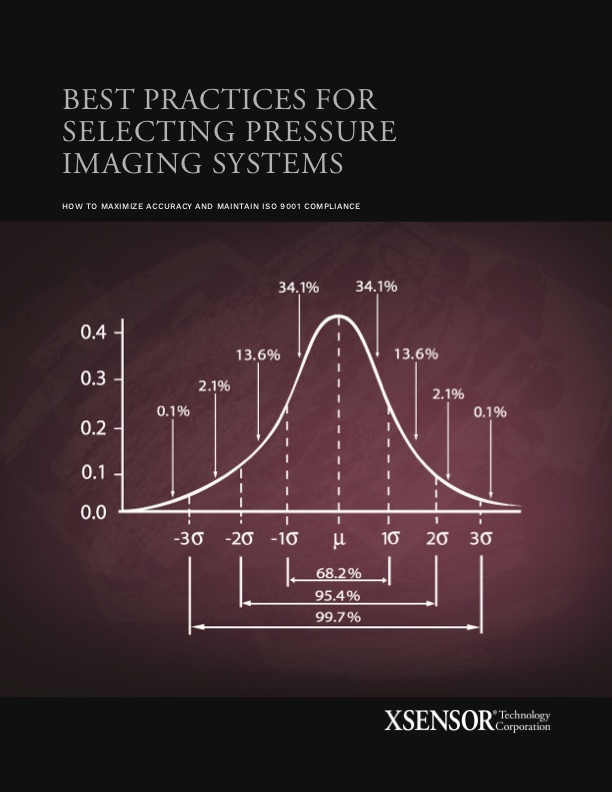

- The uncertainty of their calibration equipment is known and accounted for;

- All lab personnel are trained and technically competent;

- The methods and practices in place produce precise and valid results;

- All documentation is in place supporting practices and procedures.

YOUR PRESSURE IMAGING SENSORS MUST BE ISO/IEC 17025 COMPLIANT TO MAINTAIN ISO 9001 ACCREDITATION

In many industries, the collection of interface pressure data is an important part of both design processes and quality control procedures. Regardless of whether technicians are measuring the pressure interfaces of automotive seats, airplane tires, or hospital beds, pressure sensors used to collect data must be properly calibrated and verified to ensure confident decision-making.

Like every other type of equipment in a laboratory, the sensors used to measure interface pressure are calibrated devices. To comply with your ISO 9001 certification, your quality management system requires that you control the calibration of measurement equipment – including your pressure imaging sensors.

If the sensors used in the quality control process do not have a known uncertainty, then the entire process can be called into question. This can affect your ISO 9001 compliance, particularly for products that endanger human life when defective.

WHICH EQUIPMENT MEETS ISO/IEC 17025 STANDARDS?

Ensuring that pressure imaging equipment meets all calibration and accuracy requirements is no simple matter. Sensors must be intentionally designed with this goal in mind, as the type of sensor, the materials used to build it, and the calibration procedure will all affect performance against ISO/IEC 17025 standards.

To date, XSENSOR is an ISO/IEC 17025 certified pressure imaging sensor manufacturer. Unlike other sensors on the market, our equipment maintains calibration due to the capacitive technology design used and the unique materials used to make these sensors.

Other sensors are not able to provide the same accuracy and calibration stability due to limitations of the technology, materials and sophistication of the design. Due to poor measurement accuracy, many of these sensors require equilibration prior to use. Equilibration is a time-consuming process that introduces significant potential for systematic error, especially when attempting to compare multiple data sets from different laboratories.